Welcome once again to another entertaining look at the error codes inside the Maytag 7MMVWX655EW0 top load washer. I’m going to list each one, and explain what they are, and how to fix them if possible.

Welcome once again to another entertaining look at the error codes inside the Maytag 7MMVWX655EW0 top load washer. I’m going to list each one, and explain what they are, and how to fix them if possible.

Fortunately, this machine won‘t ruin wash day as often as some others have a habit of doing. This machine isn’t perfect, but it won’t break the bank the next time it requires a repair. And for the most part, the average repairs on this machine are not difficult. For the ones you feel you should not tackle yourself, you always have Neli standing by anytime to lend a hand.

If you’re ready, let’s dive in and take a look at the error codes for this machine. First things first. Be sure your machine is plugged in but not turned on. Follow these steps to access the Service Diagnostics:

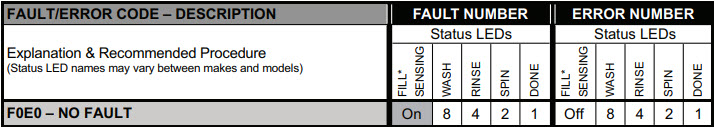

Your machine doesn’t have a display other than LEDs to show the error codes and other modes of operation. To read error codes, note they are in binary. Reference the picture above as I explain how to decipher the blinking LEDs. The first error code F0E0 indicates there are no errors in memory.

When the fill/sensing function is activated (depending on the model) and any other LED indicators are blinking during the first sequence, note the corresponding numbers for each blinking LED. Add these numbers to determine the “F” portion of the error code. Repeat this process with the second sequence of flashing LEDs to calculate the “E” portion of the code.

For instance, if the rinse and done indicators are lit, it could represent an F5 error, while the spin and done indicators being lit on the second sequence could denote an E3 error. Together, the error code is F5E3.

It will take some practice to perfect this, especially when you won’t need it (hopefully) to read any error codes that pop up. So, below are the error codes you may see with your machine. Keep in mind that sometimes a simple power cycle of the machine is all that you need to get things running again!

FAULT/ERROR CODES

F0E2 – OVER SUDS CONDITION DETECTED

Fault is displayed when Suds prevent the basket from spinning up to speed or the pressure sensor detec s rising suds level. The main control will flush water in attempt to clear Suds. If the water flush is unable to correct the problem, this may indicate:

- Not using HE detergent.

- Excessive detergent usage.

- Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

- Mechanical friction on drive mechanism or basket. (Clothing between basket and tub.)

F0E4- HIGH WATER TEMPERATURE -RINSE CYCLE

Fault is displayed when washer detects water temperature 105° or higher during rinse cycle.

- Hot water getting in. Make sure inlet hoses are connected correctly.

- If hoses are installed properly, temperature thermistor may be stuck in low resistance range.

F0E5 – OFF BALANCE LOAD DETECTED

Fault is displayed when an off-balance condition is detected.

- Check for weak suspension. Basket should not bounce up and down more than once when pushed.

- Clothing should be distributed evenly when loading.

F1E1 – MAIN CONTROL FAULT

Indicates a main control fault. Replace the main control.

F1E2 – MOTOR CONTROL FAULT

Indicates a fault of the motor control section of the main control. Replace the main control.

F2E1 – STUCK KEY

One or more keys on the User Interface were actuated for 15 consecutive seconds.

- Fault occurs during Diagnostic Test Mode if a stuck key is detected.

F2E3 – MISMATCH OF MAIN CONTROL & UI

The User Interface identification does not match the expected value in the Main Control Board.

- Fault occurs during Diagnostic Test Mode if a mismatch between main control and Ul is identified.

F3E1 – PRESSURE SYSTEM FAULT

Fault is displayed when the Main Control detects an out-of-range pressure signal.

- Check pressure hose connection from tub to pressure sensor.

- Is hose pinched, kinked, plugged, or leaking air?

F3E2-INLET WATER TEMPERATURE FAULT

Fault is displayed when the Inlet Thermistor is detected to be open or shorted.

F5E1 – LID SWITCH FAULT

Fault is displayed if lid is in locked state, but lid switch is open; control not sensing the strike in the lid lock.

- User presses START with lid open.

- The main control cannot detect the lid switch opening and closing properly.

- Strike not assembled correctly on the lid.

- Lid lock bezel not installed correctly (must be square to embossing and flush to top).

5E2 – LID LOCK FAULT

Fault is displayed if Lid Lock has not moved into locked position or motor cannot be powered.

- Lid is not closed completely due to interference.

- Check for lock interference with lock striker.

- Wash media buildup (detergent, lint, etc.) is preventing the lock mechanism from sliding.

- Main control detects open lid switch when attempting to lock.

- Main control cannot determine if lid lock is in a locked state.

F5E3 – LID UNLOCK FAULT

Fault is displayed if Lid Lock has not moved into unlocked position or motor cannot be powered.

- Check for lock interference with lock striker.

- Main control cannot determine if lid lock is in an unlocked state.

F5E4 – LID NOT OPENED BETWEEN CYCLES

Fault is displayed if the following conditions occur:

- User presses START after several consecutive washer cycles without opening lid.

F7E1 – BASKET SPEED FAULT

Fault is displayed when the main control cannot determine speed of basket, or speed changes too quickly.

- Locked rotor—check that basket, impeller, and motor can rotate freely.

- Check harness connections from main control to motor and shifter.

- Control not sensing the basket move in spin—run Tachometer Verification Mode, page 5 of Tech Sheet

- Bad motor capacitor, motor or capacitor connector disconnected, or broken wires to motor or capacitor.

- Belt is off or pulley is loose—check drive belt. Verify that belt is fully installed on both pulleys. Also, check that the pulleys are fastened securely to the motor shaft and agitator shaft.

F7E5- SHIFTER FAULT

Fault is displayed when the main control cannot determine position of shifter.

- Check harness connections from main control to motor and shifter.

- Observe shifter operation.

F7E6-MOTOR FAULT

Indicates an open clockwise or counterclockwise circuit of the motor.

F7E7 – MOTOR UNABLE TO REACH TARGET RPM

Fault is displayed when basket speed sensor detects that target RPM was not reached.

- Mechanical friction on drive mechanism or basket (clothing between basket and tub).

- Weak motor or run capacitor, or no connection to run capacitor.

- Load off balance. Clothing should be distributed evenly when loading.

F8E1 – NO FILL, LONG FILL

Fault is displayed when the water level does not change for a period of time OR water is present but main control does not detect the water level changing.

- Is water supply connected and turned on?

- Low water pressure; fill times longer than six minutes. Are hose screens plugged?

- Check for proper drain hose installation. Is water siphoning out of the drain hose?

- Drain hose must not be more than 4.5″ (114 mm) into the drain pipe.

- Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

F8E3 – OVERFLOW CONDITION

Fault is displayed when main control senses water level that exceeds the washer’s capacity.

- May signify problem with inlet water valves.

- Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

- Onboard pressure transducer or off-board pressure switch fault (depending on model).

- Not pumping—pressure switch closed or shorted in standby, or after washer completes a cycle.

- Check for proper drain hose installation. Is water siphoning out of the drain hose? Drain hose must not be more than 4.5″ (114 mm) into the drain pipe. Make sure drain hose is not seated into drain pipe, and that there is an air gap for ventilation. Ensure drain height is between 39″ (991 mm) and 8‘ (2.4 m) above the floor.

F8E5 – HOT, COLD REVERSED

Fault is displayed when the hot and cold inlet hoses are reversed.

- Make sure inlet hoses are connected correctly.

- If hoses are installed properly, temperature thermistor may be stuck in low resistance range.

F9E1 – LONG DRAIN

Fault is displayed when the water level does not change after the drain pump is on or 10 minutes.

- Is the drain hose or the drain pump clogged? Check tub sump under impeller for obstructions.

- Is the drain hose height greater than 8‘ (2.4 m)?

- Too much detergent.

- Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

There is a lot of information here that should help keep your machine running good. But as always, if you find yourself in too deep, don’t hesitate to reach out to Neli and set up a diagnosis appointment so together we can find out the solution. Good luck, and we’ll talk soon.

Need Some More Help?

Book an appointment with one of our expert technicians today.